What Is Gear Burnishing . 2.1k views 9 years ago. It is designed to remove or. This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. Hard finishing is a final machining process after hardening that results in a geometrically accurate gear. In this video brought to you by itw, learn about gear burnishing and how. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. Gear burnishing has become a valuable method of gear tooth surface improvement. It removes distortion in addition to any minor handling damage. Burnishing is a process by which a smooth hard tool (using sufficient pressure) is rubbed on the metal surface. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. This process flattens the high.

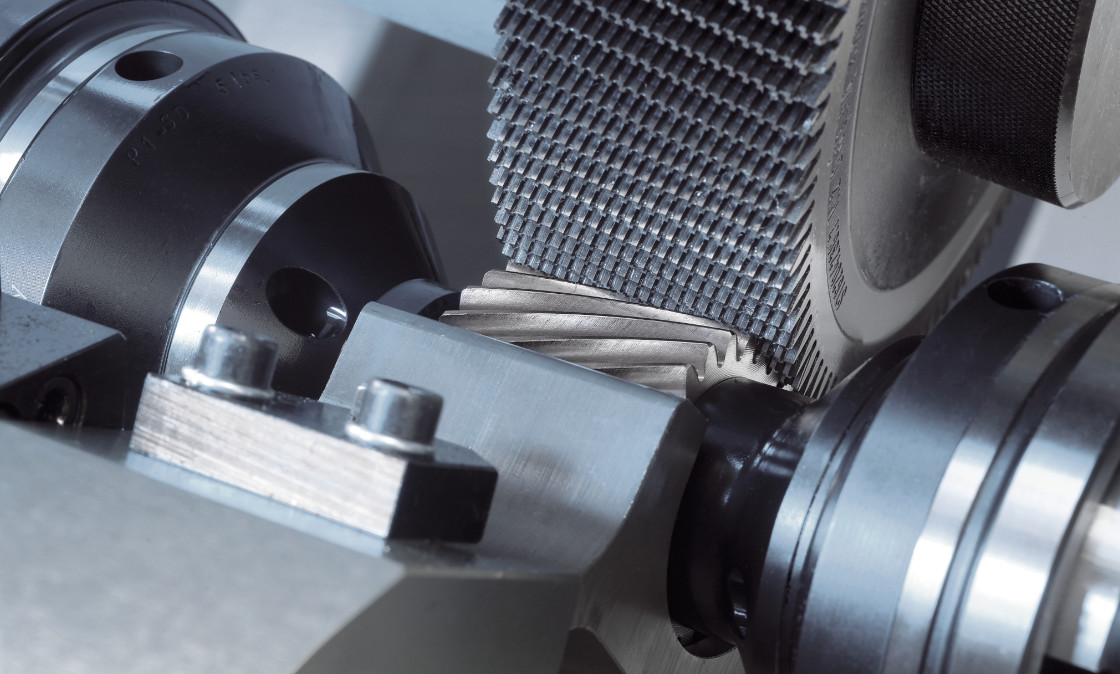

from www.emag.com

This process flattens the high. Hard finishing is a final machining process after hardening that results in a geometrically accurate gear. Burnishing is a process by which a smooth hard tool (using sufficient pressure) is rubbed on the metal surface. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. Gear burnishing has become a valuable method of gear tooth surface improvement. It removes distortion in addition to any minor handling damage. In this video brought to you by itw, learn about gear burnishing and how. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. It is designed to remove or.

Gear shaving EMAG ensures productive solutions

What Is Gear Burnishing It is designed to remove or. Gear burnishing has become a valuable method of gear tooth surface improvement. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. It is designed to remove or. Hard finishing is a final machining process after hardening that results in a geometrically accurate gear. 2.1k views 9 years ago. This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. Burnishing is a process by which a smooth hard tool (using sufficient pressure) is rubbed on the metal surface. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. This process flattens the high. In this video brought to you by itw, learn about gear burnishing and how. It removes distortion in addition to any minor handling damage.

From www.youtube.com

Gear tooth burnishing machine. YouTube What Is Gear Burnishing Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. Burnishing is a process by which a smooth hard tool (using sufficient pressure) is rubbed on the metal surface. It removes distortion in addition to any minor handling damage. This process flattens the high. Hard finishing is a final machining process after. What Is Gear Burnishing.

From www.lambdatechs.com

Low Plasticity Burnishing (LPB) Lambda Technologies What Is Gear Burnishing This process flattens the high. This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. In this video brought to you by itw, learn about gear burnishing and how. It is designed to remove or. Burnishing is a process by which a smooth hard tool (using sufficient pressure) is rubbed. What Is Gear Burnishing.

From www.mimu.com

Lapping machine Gear lapping machines for sale at Mimu Macchine U... What Is Gear Burnishing Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. It removes distortion in addition to any minor handling damage. 2.1k views. What Is Gear Burnishing.

From www.researchgate.net

Schematic illustration of the roller burnishing process Download What Is Gear Burnishing It is designed to remove or. This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. In this video brought to you by itw, learn about gear burnishing and how. 2.1k views 9 years ago. Burnishing is a method of polishing the surface of a component, through compression as opposed. What Is Gear Burnishing.

From www.youtube.com

Gear Burnishinng Process in Tamil YouTube What Is Gear Burnishing Burnishing is a process by which a smooth hard tool (using sufficient pressure) is rubbed on the metal surface. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. It removes distortion in addition to any minor handling damage. Burnishing is a. What Is Gear Burnishing.

From www.sugino.cz

Burnishing and Deburring Tools Sugino What Is Gear Burnishing It is designed to remove or. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. Gear burnishing has become a valuable method of gear tooth surface improvement. Burnishing is a process by which a smooth hard tool (using sufficient pressure) is rubbed on the metal surface. It removes distortion in addition. What Is Gear Burnishing.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations What Is Gear Burnishing Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. In this video brought to you by itw, learn about gear burnishing. What Is Gear Burnishing.

From www.cncteck.com

What is Burnishing surface treatment? What Is Gear Burnishing Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. It is designed to remove or. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. Hard finishing is a final machining process after. What Is Gear Burnishing.

From veit-tool.com

GEAR BURNISHING SYSTEMS Veit Tool & Gage What Is Gear Burnishing Gear burnishing has become a valuable method of gear tooth surface improvement. 2.1k views 9 years ago. This process flattens the high. This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. It removes distortion in addition to any minor handling damage. Burnishing is a service performed in the manufacturing. What Is Gear Burnishing.

From www.youtube.com

Burnishing Process Surface Finishing Process PPT ENGINEERING What Is Gear Burnishing It is designed to remove or. It removes distortion in addition to any minor handling damage. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. This process is commonly used to improve the appearance and functionality of metal parts, such as. What Is Gear Burnishing.

From www.zhygear.com

Design of helical gear transmission based on MATLAB ZHY Gear What Is Gear Burnishing 2.1k views 9 years ago. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. It removes distortion in addition to any minor handling damage. Burnishing is a method of polishing the surface of a component, through compression as opposed to material. What Is Gear Burnishing.

From asthegearturns.com

Hard Finishing of Gears, Part 1 As the Gear Turns What Is Gear Burnishing Hard finishing is a final machining process after hardening that results in a geometrically accurate gear. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. Gear burnishing has become a valuable method of gear tooth surface improvement. It is designed to. What Is Gear Burnishing.

From www.youtube.com

Gear Burnishing (हिन्दी ) YouTube What Is Gear Burnishing This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. In this video brought to you by itw, learn about gear burnishing and how. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. Burnishing is a service performed in the manufacturing. What Is Gear Burnishing.

From www.rapiddirect.com

Gear Manufacturing 101 A Comolete Guide on Gear Production Processes What Is Gear Burnishing This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. Gear burnishing has become a valuable method of gear tooth surface improvement. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material.. What Is Gear Burnishing.

From veit-tool.com

GEAR BURNISHING SYSTEMS Veit Tool & Gage What Is Gear Burnishing Burnishing is a process by which a smooth hard tool (using sufficient pressure) is rubbed on the metal surface. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with a hard tool or material. This process flattens the high. This process is commonly used to improve the. What Is Gear Burnishing.

From www.youtube.com

Gear Finishing Methods Shaving, Grinding, Burnishing, Lapping, Honing What Is Gear Burnishing Gear burnishing has become a valuable method of gear tooth surface improvement. This process flattens the high. This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. 2.1k views 9 years ago. It is designed to remove or. In this video brought to you by itw, learn about gear burnishing. What Is Gear Burnishing.

From www.grainger.com

METABO Burnishing Machine Set 61KK15SE 17200 RT Grainger What Is Gear Burnishing This process flattens the high. It is designed to remove or. In this video brought to you by itw, learn about gear burnishing and how. Gear burnishing has become a valuable method of gear tooth surface improvement. Burnishing is a service performed in the manufacturing industry that involves the process of polishing or smoothing a surface by rubbing it with. What Is Gear Burnishing.

From www.youtube.com

Ball Turning and Burnishing Machine YouTube What Is Gear Burnishing This process is commonly used to improve the appearance and functionality of metal parts, such as gears, bearings, and shafts. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. Gear burnishing has become a valuable method of gear tooth surface improvement. Burnishing is a service performed in the manufacturing industry that. What Is Gear Burnishing.